Understanding Overmolding: A Comprehensive Guide

Overmolding is a specialized manufacturing process that has revolutionized the production of various products across multiple industries. From consumer electronics to automotive components, overmolding provides a unique way to enhance the functionality, aesthetics, and durability of products. In this article, we will delve into what overmolding is, its advantages, applications, and how it is transforming modern manufacturing.

What is Overmolding?

Overmolding is a two-step process where one material, typically a soft thermoplastic elastomer (TPE) or rubber, is molded over a base substrate, which is often a rigid plastic or metal. The base substrate, also known as the “first shot,” is created through standard injection molding. The second material, the overmold, is then applied over the first shot, either in a separate process or simultaneously.

The materials used in overmolding are carefully selected based on their compatibility, ensuring that they bond well without the need for adhesives. The result is a single, cohesive product that combines the properties of both materials, offering enhanced performance, comfort, or protection.

Advantages of Overmolding

Overmolding offers several benefits that make it a popular choice for manufacturers:

- Enhanced Grip and Comfort: In products like handheld tools or consumer electronics, overmolding adds a layer of soft material, improving the grip and comfort for the user. This is especially important in products that are used for extended periods.

- Improved Durability: Overmolding can provide additional protection to the underlying substrate. For example, in automotive parts, the overmold can act as a shock absorber or protective layer, reducing wear and tear and extending the life of the component.

- Aesthetic Appeal: Overmolding allows for the creation of products with multiple colors or textures, enhancing their visual appeal. This is often seen in consumer goods, where the look and feel of a product are critical to its success.

- Cost-Effective Production: By combining two materials into a single process, overmolding can reduce the need for secondary operations, such as assembly or adhesive application, leading to cost savings in production.

- Versatility: Overmolding is a highly versatile process that can be applied to a wide range of products, from small electronic components to large automotive parts. It can also be used with various materials, including plastics, metals, and even glass.

Applications of Overmolding

The versatility of overmolding makes it suitable for a broad range of applications across different industries:

- Consumer Electronics: Many modern electronic devices, such as smartphones, tablets, and wearable technology, utilize overmolding to provide a comfortable grip, protect sensitive components, and enhance the overall aesthetic of the device.

- Automotive Industry: Overmolding is used extensively in the automotive sector to produce components such as gaskets, seals, and handles. The process helps improve the durability of these parts while also providing noise reduction and vibration dampening.

- Medical Devices: In the medical field, overmolding is used to create ergonomic and safe devices, such as surgical instruments and diagnostic equipment. The soft, overmolded surfaces ensure that these tools are comfortable to use and easy to clean.

- Industrial Tools: Power tools, hand tools, and other industrial equipment often feature overmolding to improve grip, reduce user fatigue, and protect the tools from damage in harsh working environments.

- Sports Equipment: Overmolding is also common in sports gear, where it enhances the performance and durability of products like golf clubs, tennis rackets, and protective gear.

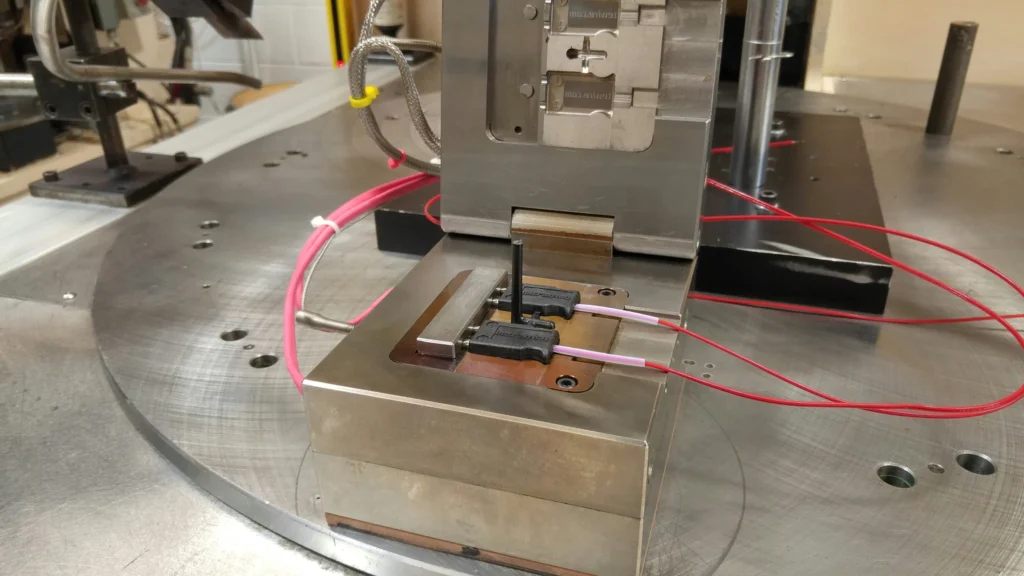

The Overmolding Process

The overmolding process typically involves the following steps:

- Injection Molding the Substrate: The first step involves creating the base substrate using standard injection molding techniques. The substrate is usually made of a rigid material like plastic or metal.

- Overmolding: The overmold material is then injected over the substrate. This can be done in the same mold or in a separate process, depending on the complexity of the design.

- Cooling and Ejection: After the overmold material has been applied, the part is cooled and then ejected from the mold.

- Finishing: Any necessary finishing touches, such as trimming excess material, are performed to complete the product.

Conclusion

Overmolding is a powerful manufacturing technique that offers numerous benefits, from enhancing product performance and durability to improving aesthetics and comfort. Its versatility and cost-effectiveness make it a valuable process in various industries, including consumer electronics, automotive, medical devices, and more. As technology advances, the possibilities for overmolding continue to expand, paving the way for innovative products that meet the evolving needs of consumers and industries alike.